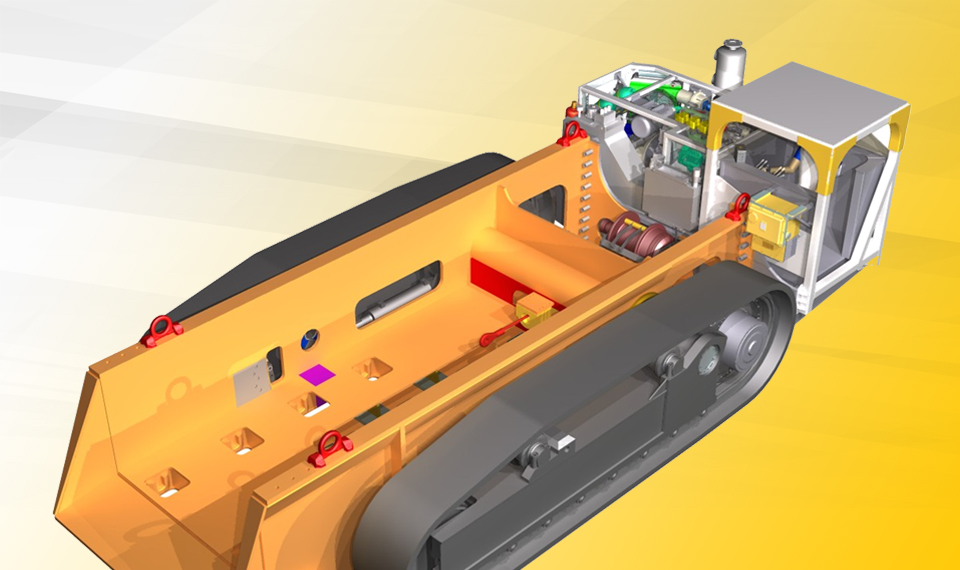

Whole-system development of construction and mining machinery

Offering a comprehensive service portfolio from concept idea to prototype testing, IBAF is a trusted partner in the development of construction and mining machinery.

Such mobile plant and equipment has to be designed for some pretty tough environments and often for a broad range of duties as well. The key parameters governing the entire development process are the load assumptions aligned to the service conditions and the load spectra appropriate to the applications specified. The derived development goals are only achievable on the basis of a holistic system approach encompassing the machine structure, the drive and control technology and the process-machine interactions.

Responsibility for the development process

IBAF assumes responsibility for development work packages on behalf of machine and component manufacturers and supports OEMs with system integration and optimization. We adopt a holistic approach extending from concept to production drawing, and from specification-compliant design to component testing in the laboratory or metrological analysis in the field.

Concepts and integrated systems

- Engineering, design and subsystem configuration

- Operating load metrology and load spectrum analysis

- Whole-system simulation from process to mechanics, hydraulics, control technology and the human-machine interface

- Virtual prototypes

Machine and cabin structures

- Tailored development of load-bearing structures

- Strength analysis and structural optimisation; lightweight concepts

- Safety-compliant design (ROPS, FOPS)

- Acoustic and vibrational optimisation

Work equipment and attachments

- Development-related kinematic studies and dynamic simulation

- Tailored engineering and design of structures and interfaces

- Development and optimisation of cutting tools and quick-change tool holder systems

Chassis

- Development of wheeled, railbound and crawler chassis and their components

- Engineering and design in accordance with required strength and wear characteristics

- Dynamic drive simulation, virtual testing for power train tuning

Drive engineering

- Development and optimisation of mechanical and hydraulic drive systems

- Integrated multi-domain system simulation

- Analysis and enhancement of energy efficiency

- System integration

Control technology

- Concept development and validation

- Software development, programming

- HIL / SIL tests

- Process engineering

- Simulation and optimization of operational processes (DEM, CFD)

- Process load assessment, functional optimisation, performance enhancement

- Energy efficiency, wear reduction, emissions reduction

Benefit from our Group-wide know-how network

The fields of competence of the IAMT Group

MOVE

Product expertise in chassis engineering. Materials handling equipment. Construction machinery. Systems development.

SAFE

Product safety testing. Drive testing. Test rig and bench construction.

FLOW

Process competence in development. Planning. Implementation.

NEXT

Product innovation through simulation. System solutions.