Process optimisation and simulation

Process simulation and visualisation alone are never going to be our end goal. Rather, our aim is always to develop a comprehensive understanding of the entire process and system architecture.

IBAF supports manufacturers and operators of machines and plant facilities in the planning, implementation and optimisation of materials handling and warehousing processes.

Analysis and optimisation of materials handling and warehousing processes

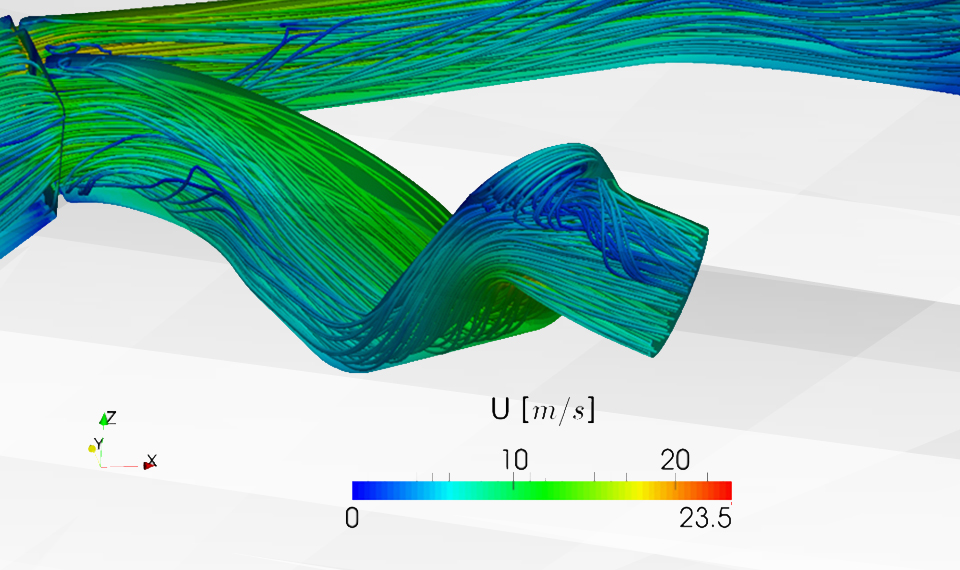

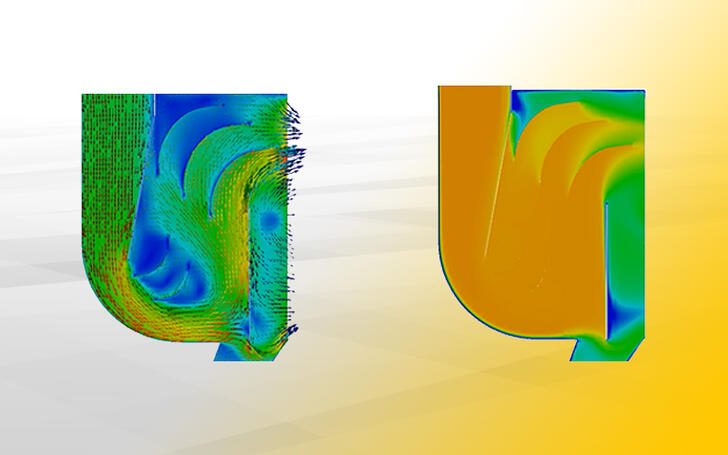

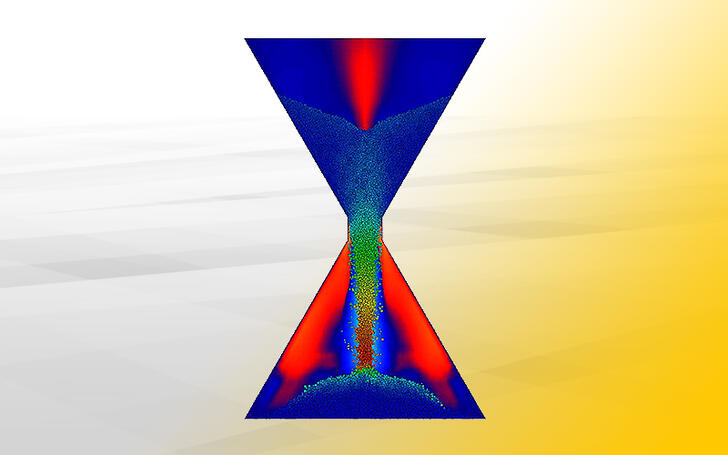

The expert analysis of relevant documents and inspection of a plant can often be sufficient for achieving a good initial understanding of the system concerned and the proposal of optimisation measures. Conversely, the measurement of process variables in fluid, particle, unit load or bulk material flows can often present considerable difficulties. We therefore analyse fluidic processes with Computational Fluid Dynamics (CFD) and material handling processes with the aid of the Discrete Element Method (DEM) using graphic 3D simulation technology. This enables the quantification of internal process forces and velocities, providing a basis for determining losses and efficiencies, tribological stresses or dust generation.

Typical areas of application

- Transfer chutes

- Continuous conveyors (screw conveyors, tube chain conveyors, belt conveyors, bucket conveyors)

- Non-continuous conveyors

- Mills

- Mixers

- Crushers

- Unit load conveyors

- Extraction systems

DEM, CFD or coupled simulations create a system understanding and thus a sound basis for targeted optimisation and further development activities. New conceptual ideas can be verified and key parameters defined for variant comparisons.

Simulation know-how for your process

Material parameterisation – The quality of simulation results depends decisively on the selected boundary conditions and material parameters. The material spectrum ranges from fine dusts to rock for crushing, the range of applications from food and pharmaceuticals manufacturing to mining and extraction.

IBAF has extensive experience and the necessary experimental equipment to parameterise free-flowing, granulated, cohesive or monolithic materials. From simple slump and pouring tests to fracture tests, by comparing real and virtual test results, the parameters appropriate to the actual, complex process simulation are determined iteratively. In this way, simulation results are generated that reliably map the actual system behaviour.

Coupled simulations – Where the boundary conditions are more complex and the material flow interacts with other physical variables, IBAF performs coupled simulations. Coupling will usually involve combinations of the following systems:

- Discrete Element Method (DEM)

- Computational Fluid Dynamics (CFD)

- Multi-Body Simulation (MBS)

- Finite Element Method (FEM)

Adding value for the customer

Offering proven practical know-how, self-developed design tools and proven simulation competence, IBAF is confident of ensuring:

- Optimal material flows

- Optimal capacity utilisation

- Minimal wear

- Reduced dust generation

- Gentle handling systems

Pressure, velocity and temperature distribution in a pre-separator

Coupled particle and flow simulation to determine the flow properties of dusts