Chassis pivot/ball joints

The IAMT Group has been specialising in pivot/ball joint and allied technologies since 1997. Test rig solutions implemented at the time still provide the basis of current test methodologies at IAMT Engineering.

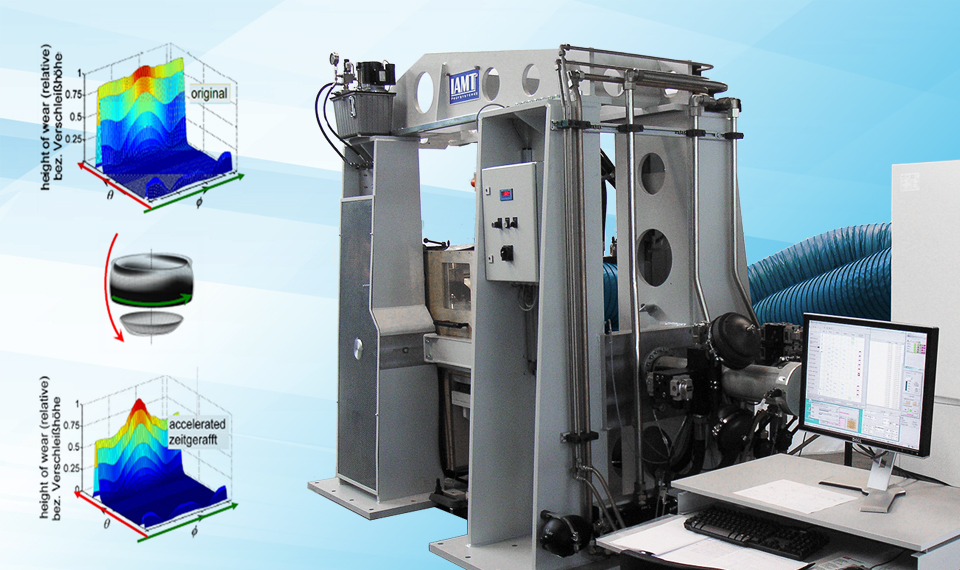

The IAMT Group has established itself as a specialist in pivot/ball joint simulation and testing. The pivot and ball joint test rigs developed and sold worldwide by Group company IAMT Prüfsysteme for environmental simulation and joint wear tests are regarded today as the standard in test system solutions for such applications. And they are being continuously further developed in accordance with the latest test standards such as AK-LH.14, VW TL and further manufacturer specifications.

Testing and simulation – pivot/ball joint expertise supplied on a single-source basis

Moreover, in a research project undertaken in collaboration with renowned German OEMs and the Ruhr University of Bochum, we have acquired groundbreaking know-how in the application of numerical joint wear simulation both as a development tool and as a means of reducing testing time.

Test services for chassis pivot/ball joints

- Environmental simulation tests to AK-LH14, VW TL 82526 and further standards (leak tightness testing, joint installation in any spigot position possible)

- Joint wear tests to AK-LH14 and further standards (3K, 4K, 5K, including environmental simulation)

- Measurement of joint characteristics (resisting torque, breakaway torque, frictional torque, spring characteristics axial and radial)

Simulation of chassis pivot/ball joint wear

- Hybrid model approach derived from mechanical model (contact pressure), thermal model (thermal resistance mesh) and tribological model (families of wear characteristics)

- Virtual prototype for development-related simulation of wear for various joint designs (socket geometry, ball geometry, position and geometry of lubricating grooves, preload values, materials)

- Virtual comparison between various test signals relating to amount of wear in the joint

- Wear-equivalent test signal acceleration/time lapse

- System analysis by simulation

- Neutral interfaces through hand-over of reduced stiffness matrices for know-how protection