Tribology and wear reduction

Rather than merely performing a tribological analysis; our aim is to create a complete understanding of the tribological system as a basis for thorough-going optimisation.

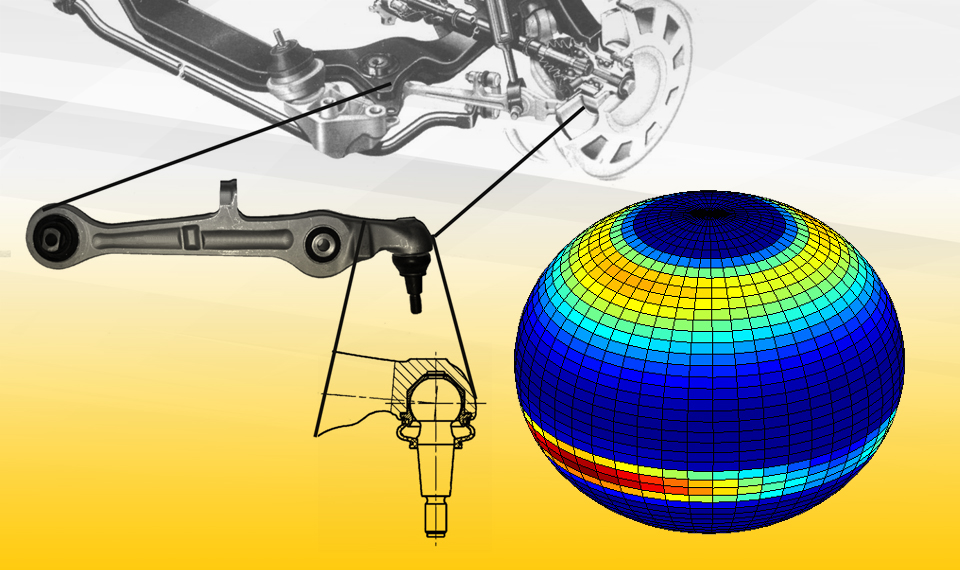

IBAF supports operators and manufacturers in the tribological analysis, assessment and optimisation of plain bearings with a particular focus on cylindrical/spherical steel/polymer pairings in the mixed friction zone.

Our expertise extends from troubleshooting to the development of specifically tribologically optimised systems, with analysis and assessment based on local measurements, laboratory tests and numerical simulation.

Basic prerequisite: Understanding the tribological system

The tribological behaviour of a sliding pair is a system property. Consequently, it is essential that the tribological system always be considered as an integrated whole. We apply a combined system analysis approach in order to ensure that this is the case:

- Measurements in the installation situation (wear, friction, deformation, temperature)

- Laboratory tests on subsystems (assemblies, components, sliding pair testing)

- Simulation of partial aspects (e.g. deformation, area contact, thermal phenomena)

Identifying complex phenomena in a real tribological system requires a holistic approach with the knowledge obtained from measurements, testing and simulation being considered as an integral whole.

Tribological problem-solving / optimisation

With a thorough understanding of the tribological system, activities can move on to problem-solving and optimisation. Here too a combination of various tools is applied in line with the problem in hand:

- Numerical simulation for the virtual investigation of variations (geometry, stiffness, thermal boundary conditions) within the installation situation

- Systematically planned laboratory tests to identify frictional and wear behaviour (DoE approach – Design of Experiments)

Final measurement of the real installation situation for verification of the level of optimisation achieved.

Simulation of component tribological behaviour

Once achieved, an extensive understanding of the tribological system can be leveraged for the purpose of simulation of the tribological behaviour of its constituent components. We offer this for oscillating planar, cylindrical and spherical sliding pairs in conjunction with comprehensive tribological analyses, with the focus on replicating the transient internal interaction between mechanical system, thermal phenomena and frictional/wear behaviour.