Operational stability

IAMT Engineering is able to draw on many years of know-how both in computational and experimental strength and durability analyses.

Our cutting-edge expertise covers not only components manufactured from ferrous and aluminium alloys but also parts made from plastics, fibre-reinforced composites and hybrid materials (CRP, GRP and hybrid components).

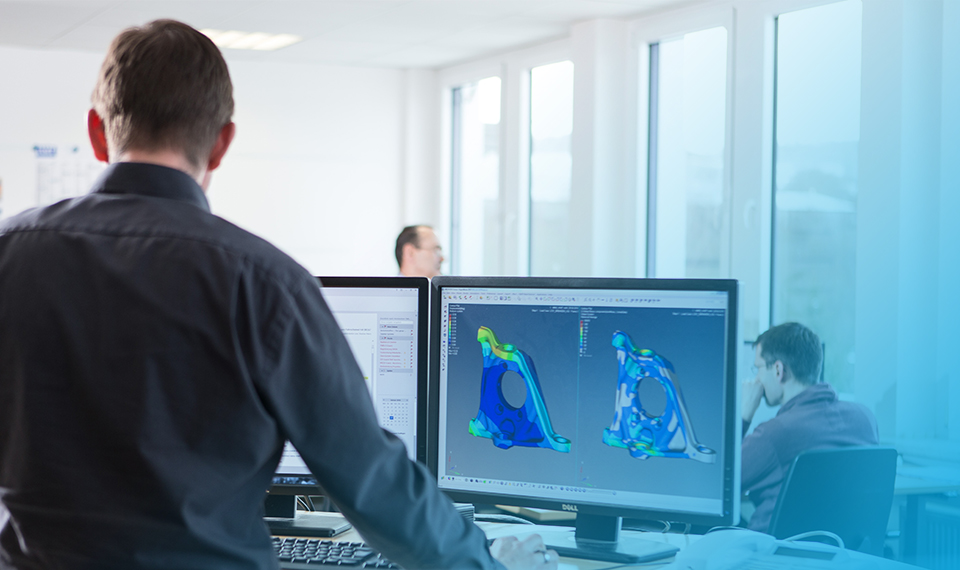

Adopting a unified approach to simulation and testing

One of the strengths of IAMT Engineering lies in its capacity to effectively combine numerical analysis tools and specially developed optimisation algorithms with a modern testing capability aligned to experimental strength, durability and service life investigations. The load data is generated from vehicle measurements and processed in MBS models, with the simulation results being constantly assessed and verified as part of a constant process of experience gain.

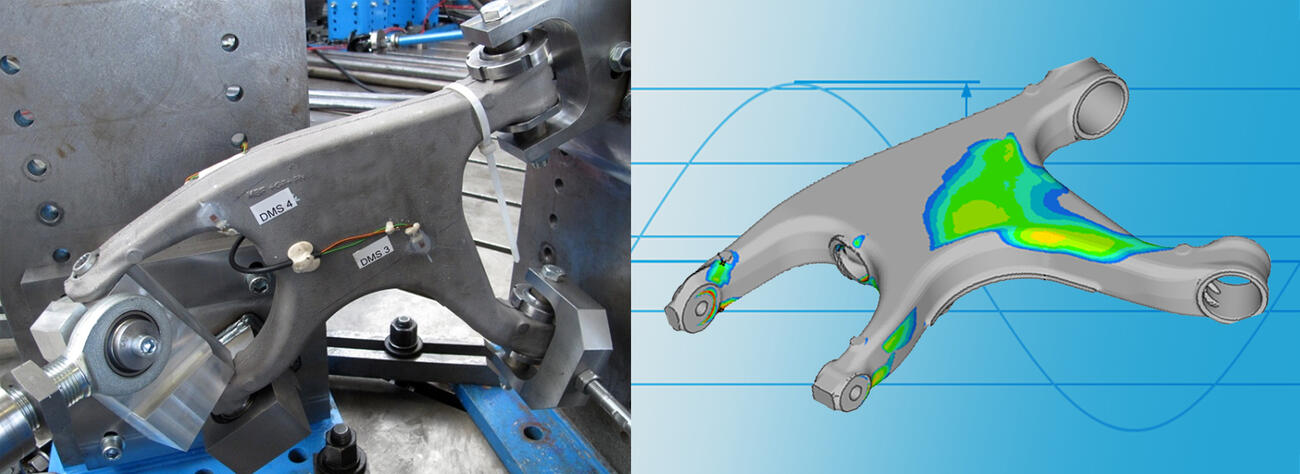

Computational durability analysis

- Static and dynamic FE analyses (linear, non-linear, transient, major deformations; use of FEM software packages such as NASTRAN, ABAQUS and ANSYS, and also MBS simulation in ADAMS and VL Motion)

- Computational fatigue analysis and assessment in the short-term yield range, endurance limit range and fatigue strength range (analytical and numerical, using fatigue analysis software FEMFAT or nCode)

- Computational weld analysis of sheet and plate (structural stresses, local concepts)

- Durability assessment of bolted joints

- Wear and service lifetime calculations for bearings and articulated joints

- Derived testing procedures (test load definition and specimen exposure regimes, accelerated/time-lapse testing )

Experimental strength analysis

- Component tests to determine static and dynamic strength (servohydraulic test rig)

- Operating stress fatigue testing of complete axle systems

- Wear testing under environmental and temperature influences

- Verification measurements (local and global stress measurements)

- Verification of test set-ups for derived testing procedures

Advice on operational stability issues

- Configuration strategy

- Durability validation system (measurement campaigns, load spectrum analysis, derived test procedures)

Operational stability as an integral part of the development process

As a customer service we will, on request, assume responsibility for the full range of integration tasks at the component level, for complete axle systems or for the complete vehicle.

Operational stability as a major component of our SAFE field of competence

Our many years of experience in experimental and numerical fatigue strength analysis form an essential platform for delivering services from within the remit of our SAFE field of competence.