Component function and endurance testing

The IAMT Engineering test bed is used for functional and endurance tests on individual components, assemblies and complete axle systems as employed in passenger vehicles, commercial vehicles, aircraft and defence systems.

The tests are carried out in accordance with client requirements or, if these are not specified, test specifications especially developed in-house by IAMT Engineering. The IAMT Engineering test bed can be used to carry out endurance tests based on operating stress fatigue testing (OSFT) procedures, block programmes, and sinusoidal or constant loading. The tests can also be carried out under controlled thermal conditions and with exposure to corrosive media.

IAMT Engineering is a trusted partner for a wide range of special testing requirements.

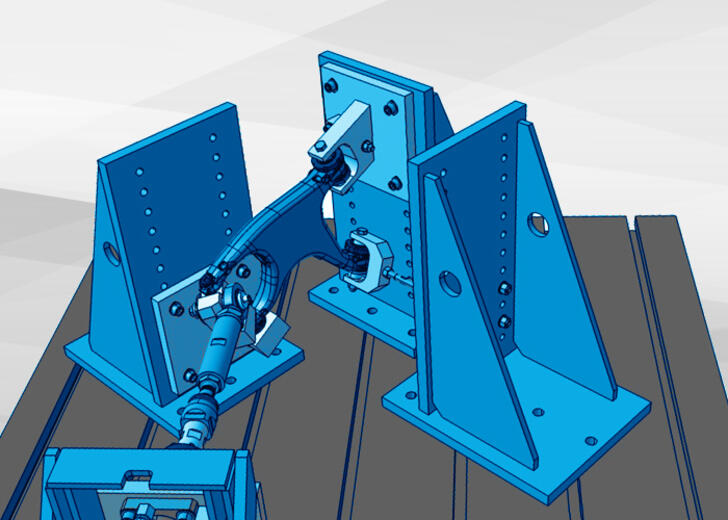

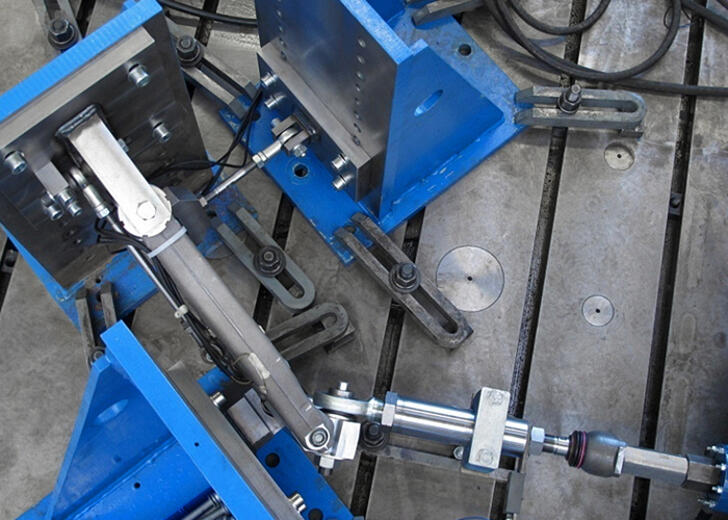

Test facilities available at IAMT Engineering for ascertaining joint wear and leak-tightness enable all the joint tests described in AK-LH-14 to be performed effectively. We have test rigs and benches for the combined leak-tightness and endurance testing of wheel bearings and have the facilities to perform tests on entire steering systems (load case: kerb push-off) and other special tests. If required, we will also partner you in the design and implementation of special-purpose jigs and fixtures for client-specific testing requirements.

Advanced test and inspection technology

- Special test rig for mechanical and electrical steering transmission with restbus (residual bus) simulation (CAN, FlexRay)

- Special test rig for steering columns (torsion tests)

- Special test rigs for wheel bearings and wheel hubs (driven, non-driven)

- Joint wear test rig (5K, test according to AK-LH14 and other specifications)

- Leak test rig for chassis pivot/ball joints (environment simulation testing to AK-LH14 and other specifications)

- Leak test rig for wheel bearings (testing to VDA-AK 5.16, dynamic corrosion testing and other specifications)

- Endurance test rigs for elastomer bearings such as chassis mounts, motor mounts, transmission mounts (2K / 3K)

- Endurance test rigs for stabilisers/dampers/shock absorbers

- Axle module tests (6K, half-axle test rigs with and without spring deflection)

- Axle system tests (12K and 16K full-axle test rigs incl. corrosion)

Test facility

Specimen application, signal iteration

Testing