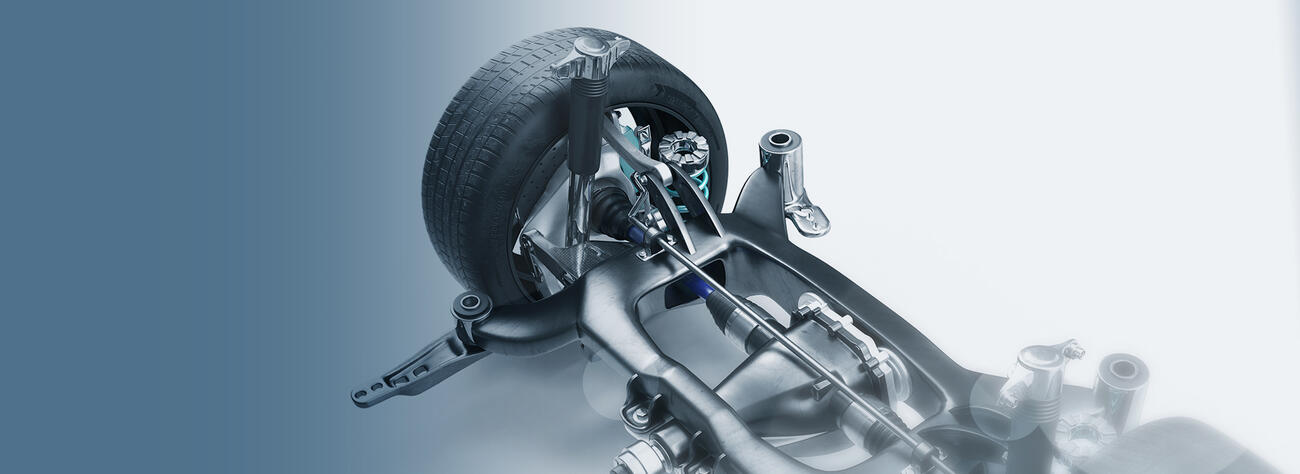

Axle systems

With development support and the assembly of complete axle systems, IAMT Chassis Systems assists automotive customers in getting their derivative and low-volume vehicles rolling.

Reducing possible risks to a minimum, the results of the axle development phase provide the platform for a product-specific concept embracing all the components required for completion of the axle system on our in-house assembly line.

Bearing press-fitting and subassembly preparation take place concurrently, with all parts being fed into interlinked stations for final assembly. The resulting axle systems are then sent out to customers worldwide for vehicle integration.

Rather than just focusing on production, our service package also includes the takt sequencing required for efficient just-in-time delivery.

Logistics

In line with our market positioning as a single-source system supplier and aware of the constant client requirement for increased efficiency and cost-effectiveness, we likewise assume responsibility for container, buffer and materials management. We offer these multiple strengths whether for mini-batch production in relation to special-purpose vehicles or low volumes for derivative-specific projects.

Process quality

All axle system fabrication and assembly work is aligned to the highest standards of quality assurance as the most reliable route to achieving and surpassing specified product properties. Our QA activities include:

- Axle system assembly - toe and camber adjustment, impact measurement

- Fittings – under torque, angle and parallelism control

- Component marking – QR code; labelling to customer specifications

- Parts documentation – batch identification, digital parts life cycle